Rubber Diaphragm Manufacturer in Kolkata

- Home |

- Rubber Diaphragm Manufacturer in Kolkata

Rubber Diaphragm Manufacturer in Kolkata

Rajasthan Rubber Co.: A Leader in Rubber Diaphragm Manufacturing

Rajasthan Rubber Co. has emerged as a premier manufacturer of high-quality rubber diaphragms, catering to a wide array of industries. With decades of expertise and a commitment to innovation, the company delivers durable and reliable solutions tailored to diverse industrial applications. We are leading Rubber Diaphragm Manufacturer in Kolkata with best quality in Kolkata location.

About Rajasthan Rubber Co.

Based in Rajasthan, India, the company specializes in the design and production of rubber diaphragms for industries such as automotive, pharmaceuticals, aerospace, and manufacturing. The organization combines advanced technology, skilled craftsmanship, and superior materials to produce diaphragms that meet global standards.

Product Range and Applications

Rajasthan Rubber Co. manufactures rubber diaphragms using various elastomers like nitrile rubber (NBR), EPDM, silicone, and Viton, ensuring compatibility with demanding environments. Key applications include:

- Valves and Pumps: Diaphragms designed to regulate fluid flow and pressure in water, chemical, and gas systems.

- Automotive Systems: Reliable diaphragms for brake boosters and fuel pumps.

- Industrial Machinery: Solutions for compressors and actuators requiring precision and durability.

- Medical Devices: Food-grade and medical-grade diaphragms for sensitive applications.

Manufacturing Excellence

Rajasthan Rubber Co. employs state-of-the-art machinery and stringent quality control measures. Their processes ensure consistency, precision, and adherence to international standards. The manufacturing unit is equipped to handle custom orders, offering tailored designs to meet specific client requirements.

Why Choose Rajasthan Rubber Co.?

- Customization: Bespoke solutions to meet unique application needs.

- Quality Assurance: Rigorous testing for durability, flexibility, and resistance to extreme conditions.

- Sustainability: Commitment to environmentally friendly manufacturing practices.

- Global Reach: Trusted by clients across industries and geographies.

Rajasthan Rubber Co. has established itself as a reliable partner for industries needing high-performance rubber diaphragms. With a focus on quality, innovation, and customer satisfaction, the company continues to set benchmarks in the manufacturing industry.

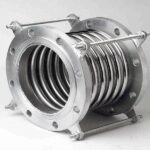

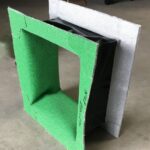

The image above provides a glimpse into Rajasthan Rubber Co.’s advanced manufacturing process, highlighting precision, technology, and the craftsmanship behind their rubber diaphragms.

Understanding Rubber Diaphragms: Essential Components in Sealing and Control Systems

Rubber diaphragms are flexible, circular membranes widely used in industrial, automotive, and mechanical systems. These components play a crucial role in sealing, controlling pressure, and facilitating movement within equipment. Typically made from durable elastomers, such as nitrile rubber, EPDM, or silicone, rubber diaphragms provide exceptional flexibility, resistance to wear, and a reliable seal against gases and liquids.

What is a Rubber Diaphragm?

A rubber diaphragm is a versatile, thin membrane designed to act as a barrier between two chambers or as a part of a control mechanism. Its primary functions include:

- Sealing: Preventing leakage between compartments or environments.

- Pressure Control: Allowing changes in pressure while maintaining separation.

- Motion Transfer: Transmitting force or movement to connected systems, such as valves or pumps.

These features make rubber diaphragms integral in applications requiring precision and durability.

Design and Materials

Rubber diaphragms are manufactured using high-performance elastomers tailored to specific applications:

- Nitrile Rubber (NBR): Offers excellent oil and fuel resistance, making it ideal for automotive and industrial use.

- EPDM: Resistant to chemicals and extreme temperatures, commonly used in HVAC and water systems.

- Silicone: Provides flexibility at both high and low temperatures, suitable for food-grade and medical applications.

Depending on the application, the diaphragm may include a reinforcing fabric layer to improve strength and longevity.

Applications of Rubber Diaphragms

- Pumps and Valves: Used to regulate flow and pressure in water, chemical, and gas systems.

- Automotive Systems: Essential in brake boosters, fuel pumps, and carburetors.

- Medical Devices: Integral in blood pressure cuffs and drug delivery systems.

- Aerospace: Employed in flight control systems due to their reliability under varying pressure conditions.

Advantages

- Flexibility and Durability: Maintains performance under constant motion or vibration.

- Cost-Effective: Long-lasting, reducing maintenance costs.

- Wide Temperature Range: Functions effectively in diverse environmental conditions.

- Customizable: Easily tailored for specific applications and configurations.

Maintenance and Challenges

Although rubber diaphragms are durable, they require regular inspections for wear, cracking, or degradation due to chemical exposure. Selecting the correct material based on the application’s demands ensures longer service life and efficiency.

Rubber diaphragms are indispensable in modern engineering and manufacturing. Their ability to provide a flexible seal while managing pressure and motion makes them an essential component across industries.

The image above illustrates a rubber diaphragm integrated into a mechanical assembly, showcasing its role in precise pressure and flow contro

What makes Rajasthan Rubber Co unique?

Their focus on quality, innovation, and customer-centric solutions sets them apart.

What industries use bellow expansion joints?

They are widely used in petrochemical, power generation, HVAC, and water treatment industries.

Can Rajasthan Rubber Co customize expansion joints?

Yes, they offer tailored solutions to meet specific industrial needs.

What materials are used in these joints?

They utilize rubber, metal, and composite materials to cater to various applications.

How do bellow expansion joints improve system efficiency?

By absorbing stress and movement, they prevent damage, ensuring long-lasting performance.